by Bruce Wells | Dec 1, 2023 | Petroleum Products

General Motors scientists discover anti-knock properties of tetraethyl lead gasoline in 1921.

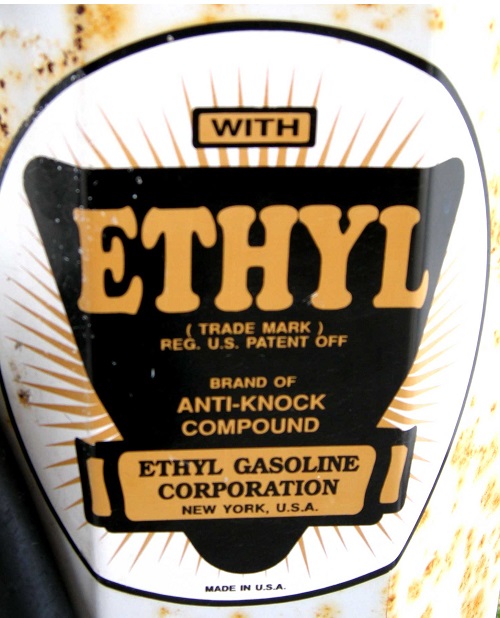

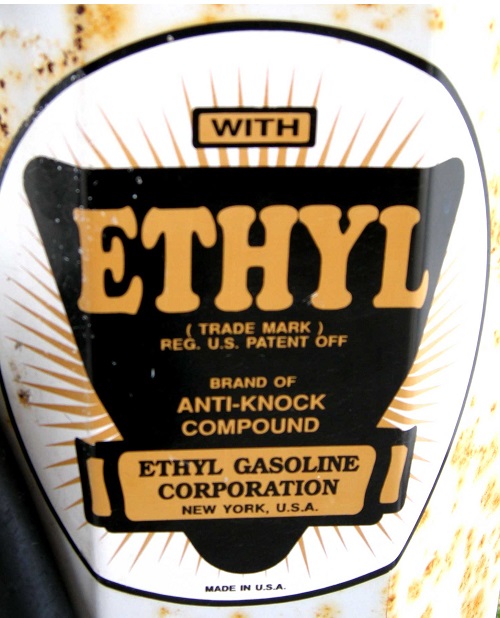

By 1923, many American motorists would be driving into service stations nationwide and saying, “Fill ‘er up with Ethyl.”

Early internal combustion engines often suffered from a severe “knocking,” the out-of-sequence detonation of the gasoline-air mixture in a cylinder. The constant shock added to exhaust valve wear and frequently damaged engines.

Automobiles powered with gasoline had been the least popular models at the November 1900 first U.S. auto Show in New York City’s Madison Square Garden.

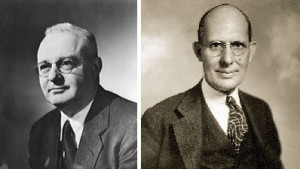

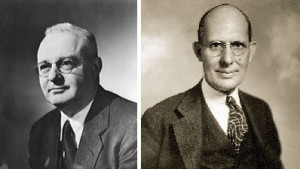

General Motors chemists Thomas Midgely Jr. and Charles F. Kettering tested many gasoline additives, including arsenic.

On December 9, 1921, after five years of lab work to find an additive to eliminate pre-ignition “knock” problems of gasoline, General Motors researchers Thomas Midgely Jr. and Charles Kettering discovered the anti-knock properties of tetraethyl lead.

Early experiments at GM examined the properties of knock suppressors such as bromine, iodine and tin — comparing these to new additives such as arsenic, sulfur, silicon and lead.

The world’s first anti-knock gasoline containing a tetra-ethyl lead compound went on sale at the Refiners Oil Company service station in Dayton, Ohio. A bolt on “Ethylizer” can be seem running vertically alongside the visible reservoir. Photo courtesy Kettering/GMI Alumni Foundation.

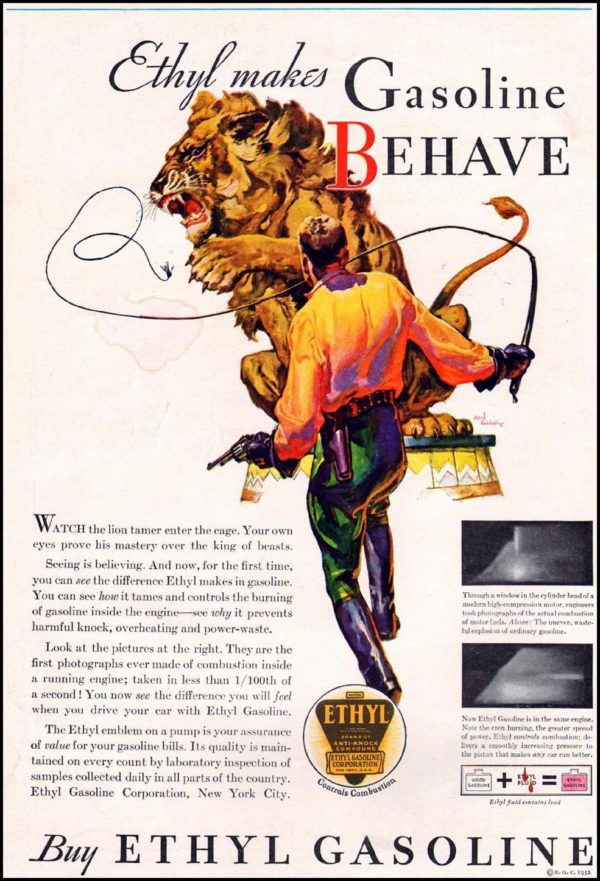

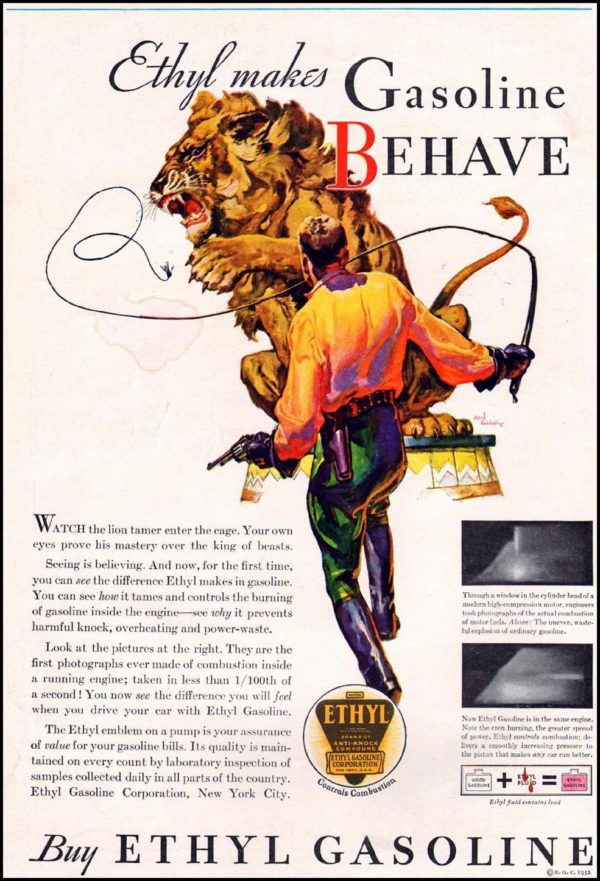

When the two chemists synthesized tetraethyl lead and tried it in their one-cylinder laboratory engine, the knocking abruptly disappeared. Fuel economy also improved. “Ethyl” vastly improved gasoline performance.

“Ethylizers” debut in Dayton

Although being diluted to a ratio of one part per thousand, the lead additive yielded gasoline without the loud, power-robbing knock. With other automotive scientists watching, the first car tank filled with leaded gas took place on February 2, 1923, at the Refiners Oil Company service station in Dayton, Ohio.

In the beginning, GM provided Refiners Oil Company and other service stations special equipment, simple bolt on adapters called “Ethylizers” to meter the proper proportion of the new additive.

“By the middle of this summer you will be able to purchase at approximately 30,000 filling stations in various parts of the country, a fluid that will double the efficiency of your automobile, eliminate the troublesome motor knock, and give you 100 percent greater mileage,” Popular Science Monthly reported in 1924.

By the late 1970s, public health concerns resulted in the phase-out of tetraethyl lead in gasoline, except for aviation fuel.

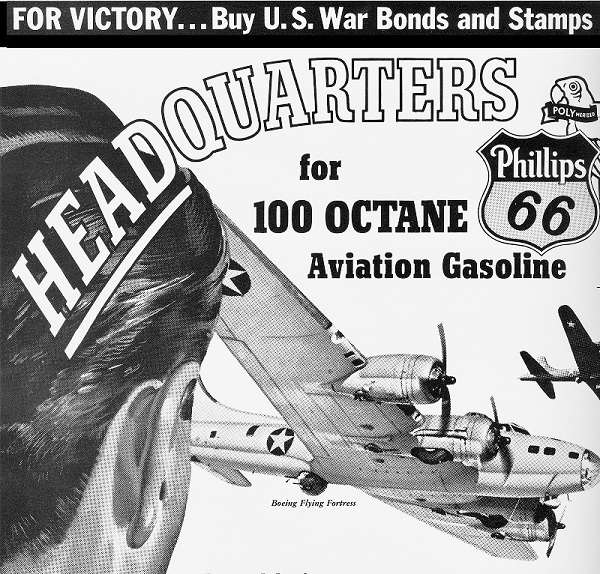

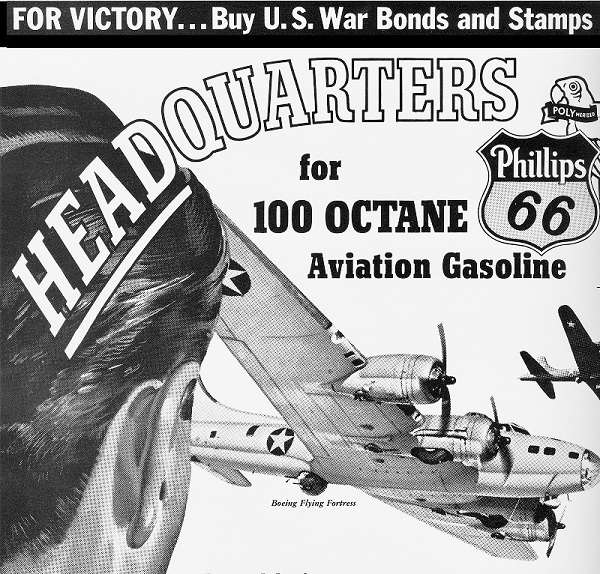

Anti-knock gasoline containing a tetraethyl lead compound also proved vital for aviation engines during World War II, even as danger from the lead content increasingly became apparent.

Powering Victory in World War II

Aviation fuel technology was still in its infancy in the 1930s. The properties of tetraethyl lead proved vital to the Allies during World War II. Advances in aviation fuel increased power and efficiency, resulting in the production of 100-octane aviation gasoline shortly before the war.

Phillips Petroleum – later ConocoPhillips – was involved early in aviation fuel research and had already provided high gravity gasoline for some of the first mail-carrying airplanes after World War I.

Phillips Petroleum produced tetraethyl leaded aviation fuels from high-quality oil found in Osage County, Oklahoma, oilfields.

Phillips Petroleum produced aviation fuels before it produced automotive fuels. The company’s gasoline came from the high-quality oil produced from Oklahoma’s Seminole oilfields and the 1917 Osage County oil boom.

Although the additive’s danger to public health was underestimated for decades, tetraethyl lead has remained an ingredient of 100 octane “avgas” for piston-engine aircraft.

Tetraethyl lead’s Deadly Side

Leaded gasoline was extremely dangerous from the beginning, according Deborah Blum, a Pulitzer-Prize winning science writer. “GM and Standard Oil had formed a joint company to manufacture leaded gasoline, the Ethyl Gasoline Corporation,” she noted in a January 2013 article. Research focused solely on improving the formula, not on the danger of the lead additive.

A 1932 magazine ad promoted wildly improved high-compression engine performance.

“The companies disliked and frankly avoided the lead issue,” Blum wrote in “Looney Gas and Lead Poisoning: A Short, Sad History” at Wire.com. “They’d deliberately left the word out of their new company name to avoid its negative image.”

In 1924, dozens were sickened and five employees of the Standard Oil Refinery in Bayway, New Jersey, died after they handled the new gasoline additive.

By May 1925, the U.S. Surgeon General called a national tetraethyl lead conference, Blum reported, and an investigative task force was formed. Researchers concluded there was ”no reason to prohibit the sale of leaded gasoline” as long as workers were well protected during the manufacturing process.

So great was the additive’s potential to improve engine performance, the author notes, by 1926 the federal government approved continued production and sale of leaded gasoline. “It was some fifty years later – in 1986 – that the United States formally banned lead as a gasoline additive,” Blum added.

By the early 1950s, American geochemist Clair Patterson discovered the toxicity of tetraethyl lead; phase-out of its use in gasoline began in 1976 and was completed by 1986. In 1996, EPA Administrator Carol Browner declared, “The elimination of lead from gasoline is one of the great environmental achievements of all time.”

Learn more about high-octane fuel in Flight of the Woolaroc and and early engines in Cantankerous Combustion – First U.S. Auto Show.

_______________________

Recommended Reading: An Illustrated Guide to Gas Pumps (2008); Unleaded: How Changing Our Gasoline Changed Everything (2021). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2008); Unleaded: How Changing Our Gasoline Changed Everything (2021). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website, expand historical research, and extend public outreach. For annual sponsorship information, contact bawells@aoghs.org. © 2023 Bruce A. Wells. All right reserved.

Citation Information – Article Title: “Ethyl Anti-Knock Gas.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/products/tetraethyl-lead-gasoline. Last Updated: December 2, 2023. Original Published Date: December 7, 2014.

by Bruce Wells | Nov 16, 2023 | Petroleum Products

Making “wet gas” in early 20th century Oklahoma oilfields.

When Robert Galbreath and Frank Chesley completed their Ida Glenn No. 1 well on November 22, 1905, they revealed another giant oilfield south of Tulsa. The discovery well, drilled with cable-tool technology, struck oil-bearing sands at depth of only 1,450 feet. (more…)

by Bruce Wells | Jul 5, 2023 | Petroleum Products

Highly refined propellant began as “coal oil” for lamps.

A 19th century petroleum product made America’s 1969 moon landing possible. On July 16, 1969, kerosene rocket fuel powered the first stage of the Saturn V of the Apollo 11 mission.

Four days after the Saturn V launched Apollo 11, astronaut Neil Armstrong announced, “Houston, Tranquility Base here. The Eagle has landed.” His historic achievement rested on new technologies – and tons of fuel first refined for lamps by a Canadian in 1848.

Powered by five first-stage engines fueled by “rocket grade” kerosene, the Saturn V remains the tallest, heaviest and most powerful rocket ever built.

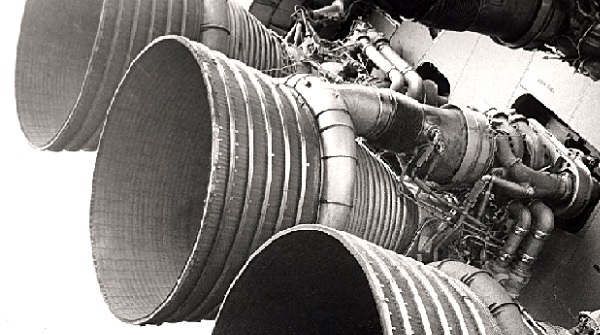

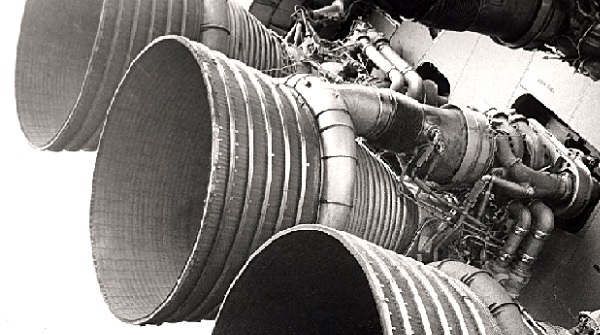

During launch, five Rocketdyne F-1 engines of the massive Saturn V’s first stage burn “Rocket Grade Kerosene Propellant” at 2,230 gallons per second – generating almost eight million pounds of thrust.

The F-1 engines of the Saturn V first stage at the U.S. Space and Rocket Center in Huntsville, Alabama. Photos courtesy NASA.

Saturn’s rocket fuel is highly refined kerosene RP-1 (Rocket Propellant-1 or Refined Petroleum-1) which, while conforming to stringent performance specifications, is essentially the same “coal oil” invented in the mid-19th century.

Canadian physician and geologist Abraham Gesner began refining an illuminating fuel from coal in 1846. “I have invented and discovered a new and useful manufacture or composition of matter, being a new liquid hydrocarbon, which I denominate Kerosene,” he noted in his patent.

The father of American rocketry, Robert Goddard, in 1926 used gasoline to fuel the world’s first liquid-fuel rocket, seen here in its launch stand. Photo courtesy Library of Congress.

By 1850, Gesner had formed a company that installed lighting in the streets in Halifax, Nova Scotia. In 1854, he established the North American Kerosene Gas Light Company at Long Island, New York.

Although he had coined the term kerosene from the Greek word keros (wax), because his fluid was extracted from coal, most consumers called it “coal oil” as often as they called it kerosene.

By the time of the first U.S. oil well drilled by Edwin Drake in 1859, a Yale scientist (hired by the well’s investors) reported oil to be an ideal source for making kerosene, far better than refined coal. Demand for kerosene refined from petroleum launched the nation’s exploration and production industry.

Although electricity would replace kerosene lamps and gasoline dominate 20th century demand for a transportation fuel, kerosene has remained a power fuel choice.

Jet Car Racers

On November 7, 1965, California race car driver Art Arfons set the land-speed record at 576.553 miles per hour at Utah’s Bonneville Salt Flats. The Ohio drag racer’s home-made Green Monster was powered by JP-4 fuel (a 50-50 kerosene-gasoline blend), in an afterburner-equipped F-104 Starfighter turbojet jet engine.

A kerosene-gasoline blend powered the F-104 jet engine of the Green Monster to world records,.

Nathan Ostrich, who built of the first jet car in 1962, reached a speed in excess of 330 mph on the famous one-mile strip in his Flying Caduceus. His racer used a General Electric J47 engine originally designed for the North American F-86 Sabre jet fighter. Arfon set the world land-speed record three times between 1964 and 1965, in what became known as “The Bonneville Jet Wars.”

Record challenger Craig Breedlove’s Spirit of America Sonic 1 in 1965 used a jet engine from a an F-4 Phantom II to defeat the Green Monster and set a record of 600.601 mph, which lasted until 1970, when the Blue Flame Natural Gas Rocket Car reached 630.388 mph.

Kerosene Rockets

Kerosene’s ease of storage and stable properties attracted early rocket scientists like America’s Robert H. Goddard and Germany’s Wernher von Braun. During World War II, kerosene fueled Nazi Germany’s notorious V-2 ballistic missiles.

Decades of post-war rocket engine research and testing led to the Saturn V’s five Rocketdyne F-1 engines. “The F-1 remains the most powerful single-combustion chamber liquid-fueled rocket engine ever developed, according to David Woods, author of How Apollo Flew to the Moon, 2008.

The Rocketdyne F-1 engines, 19 feet tall with nozzles about 12 feet wide, include fuel pumps delivering 15,471 gallons of RP-1 per minute to their thrust chambers. The Saturn V’s upper stages burn highly volatile liquid hydrogen (and liquid oxygen in all three stages). The five-engine main booster hold 203,400 gallon of RP-1. After firing, the engines can empty the massive fuel tank in 165 seconds.

Kerosene fueled the Saturn V’s five main engines used for getting Apollo astronauts to the moon. NASA photo detail.

The Apollo 11 landing crowned liquid-rocket fuel research in America dating back to Goddard and his 1914 “Rocket Apparatus” powered by gasoline. In March 1926, Goddard launched the world’s first liquid-fuel rocket from his aunt’s farm in Auburn, Massachusetts.

Although gasoline will be replaced with other propellants, including the liquid hydrogen and liquid oxygen used in the space shuttle’s external tank, RP-1 kerosene continues to fuel spaceflight.

Cheaper, easily stored at room temperature, and far less of an explosive hazard, the 19th century petroleum product today fuels first-stage boosters for the Atlas, Delta II, Antares, and the latest SpaceX rockets. Reusable SpaceX Falcon 9 rockets have nine Merlin engines burning kerosene fuel and generating 1.7 million pounds of thrust.

Last launched in 1972, the Saturn V remains the most powerful rocket ever built.

_______________________

Recommended Reading: Stages to Saturn: A Technological History of the Apollo/Saturn Launch Vehicles (2003). As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2003). As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves oil history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2023 Bruce A. Wells.

Citation Information – Article Title: “Kerosene Rocket Fuel.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL:https://aoghs.org/products/kerosene-rocket-fuel. Last Updated: July 5, 2023. Original Published Date: July 12, 2015.

by Bruce Wells | May 16, 2023 | Petroleum Products

A 1903 petroleum product named for the French word for chalk, craie, and English adjective oily, oleaginous.

Petroleum has provided products worldwide, with some hiding in plain sight. For Pennsylvania’s Benny & Smith Company, common oilfield paraffin changed the company’s future by coloring children’s imaginations. Before inventing Crayola crayons, the partners patented a “dustless chalk” popular with teachers, a red oxide for paints, and Staonal — “stay-on-all” — the blackest of all markers.

In 1881, three decades after America’s first oil well at Titusville, Pennsylvania, Crayola crayons began with a petroleum refining patent by Edwin Binney to make carbon black, an intensely black pigment.

Binney and his partner C. Harold Smith had launched their company selling inks, black polishes, and a chalk for schoolroom blackboards. Pennsylvania’s booming oilfields would prove key to their success, beginning with using natural gas in a patented “Apparatus for the Manufacture of Carbon Black.”

Binney & Smith Company later would add oilfield paraffin — the bane of oil producers since it clogged wells — and mix in colors to create a petroleum product named Crayola®.

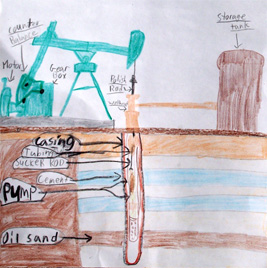

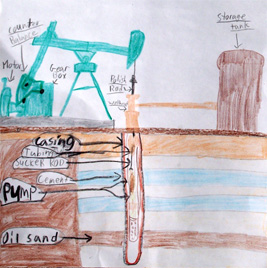

Fifth-grader’s skillful use of crayons to illustrate oil production. Image courtesy Pioneer Oil Museum of New York, Bolivar.

Manufacturing Carbon Black

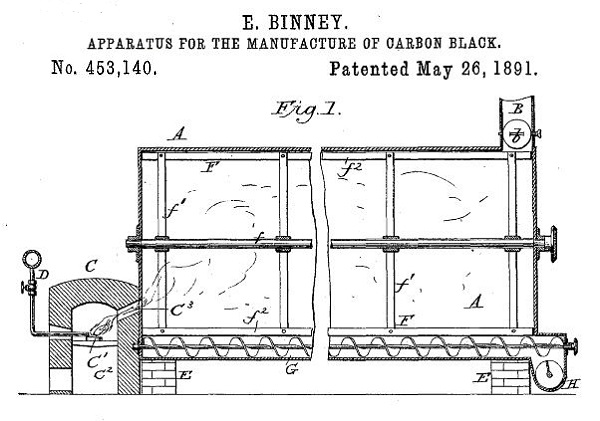

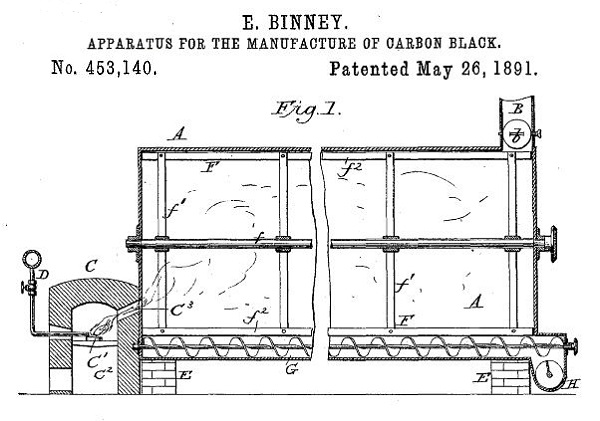

On May 28, 1891, Binney received a patent for the company’s method to efficiently produce a fine, soot-like substance more intensely black than any other pigment in use at the time.

“The objects of my invention are to manufacture lamp-black from oil in an improved and economical manner, whereby waste of the product and unnecessary expenditure of labor are avoided,” Binney noted in his patent application.

His patent (No. 453,140) proclaimed a process to “manufacture carbon-black from gas in such a manner as to obtain improved quality of black which shall have the soft flaky texture of lamp-black made in ordinary ways.”

Binney & Smith Company received an 1891 patent for an “Apparatus for the Manufacture of Carbon Black,” which produced a fine, soot-like black pigment – far better than any other in use.

The young U.S. petroleum industry, rapidly expanding its refineries to fuel kerosene for lamps, supplied Binney & Smith Company the oil and natural gas feedstock for the company’s carbon black. The heat and smoke resulting from the burning gas was directed to cool in revolving metal drums.

The company refining process produced a fine, soot-like substance of incredible blackness — a better pigment than any other then used. Binney & Smith’s carbon black received an award at the 1900 Paris Exposition, a world’s fair of the century’s achievements.

It was not long before the inventors mixed their carbon black product with oilfield paraffin and other waxes to introduce a paper-wrapped black crayon marker for crates and barrels. The marker was promoted as being able to “stay on all” and accordingly named “Staonal.”

Resulting from an 1891 carbon black patent, Binney & Smith added oilfield paraffin to produce a black marker. Staonal is still sold.

Staonal became a highly successful company product, but was too laden with carbon black to be safe for use by children. Earlier, the company had found success manufacturing “dustless chalk” for schoolrooms and a red iron oxide for a red paint farmers used on barns.

Classroom Chalk

Although they longed for color, students in Alice Stead Binney’s classroom had to settle for dustless chalk. In fact, An-Du-Septic dustless chalk was so popular among turn-of-the-century teachers that it won a Gold Medal at the 1904 World’s Fair in St. Louis.

Teachers like Alice loved the tidy new product, but their choices were limited. Pencils of the day were primitive, with square “leads” made from a variety of clays, slates, and graphite. Color writing implements were the toxic and expensive imports of artists, best kept away from schoolchildren.

Experiments in 1902 produced An-Du-Septic, a white dustless chalk soon popular with teachers. Photo courtesy Benny and Smith Company.

Alice’s husband Edwin, and his cousin, C. Harold Smith, created An-Du-Septic chalk as a consequence of expanding their pigment business into the sideline production of slate pencils for schools.

In Easton, Pennsylvania, the Binney & Smith Company, formerly the Peekskill Chemical Works, was best known for its production of red iron oxide and carbon black for paints, inks, and stove and shoe polishes. That would change.

Slate pencils and the very successful An-Du-Septic dustless chalk nonetheless put Binney & Smith salesmen into America’s classrooms. The company’s sales force listened to teachers and learned there would be a ready market for inexpensive, non-toxic, brightly colored crayons.

“Crayola” from Oilfield Paraffin

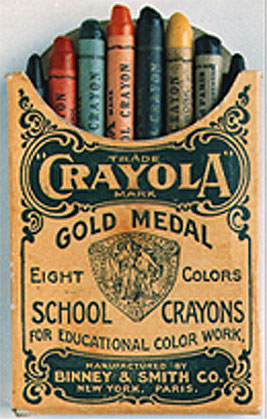

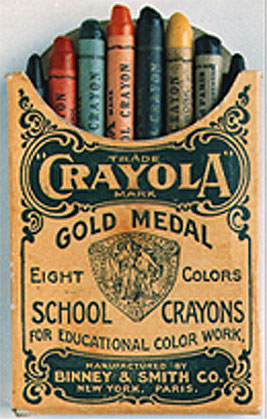

By 1903, Binney & Smith was ready to launch a new product that would change childhood forever. Alice Binney provided the historic name by combining the French word for chalk, craie, with an English adjective meaning oily, oleaginous, creating Crayola®.

Manufacturing was based on small batches of carefully measured and hand-mixed pigments, paraffin, talc and other waxes. Paper labels were individually rolled by hand and pasted onto each crayon.

The finished products were hand packed into individual boxes and shipped in wooden crates. Sixteen Crayola crayons sold for 10 cents; eight for 5 cents: red, yellow, orange, green, blue, violet, black, and brown. Crayola was an instant hit.

Binney and Smith produced the first box of eight Crayola crayons in 1903 — red, orange, yellow, green, blue, violet, brown, and black.

The company’s proprietary formulas remain a closely guarded secret as demand for its crayons has continued to grow around the world. Production capacity reportedly is more than four million crayons every day, thanks to oilfield paraffin from distant petroleum refineries delivered to Crayola’s Easton factory in railroad tank cars.

In January 2007, Binney & Smith became Crayola LLC in recognition of the company’s number one brand. The company is now known as Crayola. Crayola has grown to become a $500 million dollar a year business — a successful union of the petroleum industry to the colorful world of children’s imaginations.

“This organizational and name change showcases the company’s Crayola brand, sold by Binney & Smith since 1903,” explained the company, which also opened a museum in Easton. Crayola is sold in more than 80 countries, “and represents innovation, fun, kids and quality.”

As paraffin continued to find its way into more products (see The Crude History of Mabel’s Eyelashes), in 1912, Binney & Smith’s carbon black was used for the first time to make black tires.

Carbon Black Hits the Road

Until carbon black was added to improve durability, auto tires were white. Then in 1839, bankrupt Philadelphia hardware merchant and erstwhile inventor Charles Goodyear accidentally dropped rubber and sulfur on a hot stove top. The rubber charred like leather yet remained elastic, a discovery that led to “vulcanization.”

With the new process, natural rubber could be transformed into an industrial product with innumerable uses. Goodyear’s famous lawyer, Daniel Webster, praised his client’s invention. “It introduces quite a new material into the manufacture of the arts, that material being nothing less than elastic metal,” Webster proclaimed.

Automobile tires were the ideal application for this new product. Between 1895 and 1905, more than 77,000 new automobiles were registered in the United Stated (See Cantankerous Combustion — First U.S. Auto Show).

The tires of this 1904 Oldsmobile Model N Touring Runabout were not chosen for their color. Until B.F. Goodrich introduced “carbon black” into the vulcanizing process in 1910, auto tires were white.

The nation’s maximum speed limit in most cities was 10 mph, and automobile tires were white. Natural rubber pigments and zinc oxide used in the manufacturing process gave tires their color.

In 1910, the B.F. Goodrich Company found that adding carbon black to the vulcanizing process dramatically improved strength and durability. The material came from controlled combustion of both oil and natural gas. Its use in tires created an immense market – initially consuming one pound of carbon black for each two pounds of rubber.

As the automobile industry grew, so did demand for tires and for carbon black. By 1931, Texas was producing more than 200 million pounds of carbon black annually from just 31 plants – 75 percent of America’s total.

Today, most of America’s carbon black is still produced in Texas and Louisiana. Demand remains closely associated with automobile tires. Cabot Corporation, founded in Pennsylvania in 1882, is the largest U.S. producer of intensely black material. In 2017, the company reported having 44 manufacturing plants in 21 countries and revenues of more than $2.7 billion.

Paraffin crayons and carbon black are among many petroleum products.

_______________________

Recommended Reading: – Crayola Creators: Edward Binney and C. Harold Smith, Toy Trailblazers (2016); Carbon Black, Its Manufacture, Properties, and Uses (2018); The B.F. Goodrich Story Of Creative Enterprise 1870-1952

(2016); Carbon Black, Its Manufacture, Properties, and Uses (2018); The B.F. Goodrich Story Of Creative Enterprise 1870-1952 (2010). Your Amazon purchases benefit the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2010). Your Amazon purchases benefit the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an annual AOGHS supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2023 Bruce A. Wells.

Citation Information – Article Title: “’Carbon Black & Oilfield Crayons.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/products/oilfield-paraffin. Last Updated: May 16, 2023. Original Published Date: September 1, 2007.

by Bruce Wells | May 1, 2023 | Petroleum Products

Tinsmith recreates popular 19th century lamps that used angled burners to lower chances of explosion.

Prior to the Civil War, the most popular lamp fuel in the country was a “burning fluid” called camphene, a volatile combination of turpentine and alcohol with camphor oil added for aroma. Until replaced by the far safer lamp fuel kerosene, two-wicked camphene lamps provided light for much of America.

Camphene’s explosive mixture required a double burner, according to Ron Miller, a self-taught tinsmith and “hands-on historian.” He became fascinated by the designs of these early illuminating lamps.

Jim Miller’s 19th century lamp tin recreations, left to right: a whale oil burner; an 1842 patented lard oil burner; a “Betty Lamp” fueled by fat; and a typical camphene two-wicked lamp.

“This adventure has deepened my appreciation for past craftsmanship and the intelligence of common place things in early America,” explained Miller in his 2012 For the love of History blog. “Besides, now I have all this cool stuff to play (teach) with.”

The key to learning about early to mid-19th century oil lamps was to study their burners, Miller noted (see Camphene to Kerosene Lamps), adding, “each type of fuel needed a specific style of burner to give the best light.”

Although most of the fuels have become obsolete, Miller “wanted to faithfully replicate the burners, in order to understand how they evolved,” he said, adding, “For the time being, substitute fuels would have to do.”

Miller fashioned tin into period lamp designs, including one fueled by fat — a “Betty Lamp” that “has an ancestry extending clear back to the Romans but had been improved on over time.” He also recreated a whale oil lamp, circa 1850, and a patented lard oil burner of 1842 (the lard needed to be warmed, to improve its fluidity).

Miller also created a lard oil lamp using a burner patent from 1842.

“These tubes never extend down past the mounting plate and never have slots for wick adjustment. Apparently, any heat added to the fuel caused an accumulation of gases and the possibility of an explosion,” he noted. Most surviving original burners have little covers to snuff out the flame and keep the fuel from evaporating.

“The style of lamp I chose to replicate is sometimes called a petticoat lamp by collectors for the flared shape of the base. Camphene lamps are often mislabeled as Whale Oil lamps but the difference is obvious once you know your burners,” Miller concluded about his replica.

“In case you wondered, my lamp burns modern lamp oil as I don’t need to kill myself in the pursuit of history,” the tinsmith added.

_______________________

Recommended Reading: Oil Lamps The Kerosene Era In North America (1978). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(1978). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. Copyright © 2023 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Making a Two-Wick Camphene Lamp.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/products/two-wick-camphene-lamp. Last Updated: May 1, 2023. Original Published Date: March 11, 2018.

.

by Bruce Wells | Apr 27, 2023 | Petroleum Products

Standard Oil scientists patented a process they called “thermal cracking.”

Beginning in the 1890s, the Whiting refinery of Standard Oil Company of Indiana first produced kerosene for lamps and later gasoline for autos to meet growing consumer demand.

Seventeen miles east of Chicago, Standard Oil Company of New Jersey began construction on a massive refinery complex in early May 1889.

BP completed a multi-year, multi-billion dollar modernization project at the Whiting refinery in 2013. Photo courtesy Hydrocarbon Processing magazine.

Using advanced refining processes introduced by John D. Rockefeller, it would become the largest in the United States. The 1,400-acre complex, once operated by Amoco, was acquired by the British Petroleum Company in 1998.

After acquiring Amoco and the refinery, British Petroleum became BP Amoco. That name was shorted to BP in 2001 after mergers with ARCO and Castrol. In 2021, the company brand changed to BP in lower-case type, often with the tagline “Beyond Petroleum,” and a stylized yellow and green sun.

The Whiting plant refined 152,000 barrels of oil per day in 2021.

Refining “Sour Crude”

About one month after construction of the then 235-acre refinery began, Rockefeller established a locally based subsidiary by incorporating Standard Oil Company of Indiana on June 18, 1889. The new company began processing oil at its Whiting refinery within a year.

In its early years, the Indiana refinery processed a sulfurous “sour crude” from the Lima, Ohio, oilfields — transported on Rockefeller controlled railroads. Most Americans, already putting out their tallow candles to buy lamps fueled with whale oil, lard, or the less costly but volatile camphene, embraced a new fuel — “rock oil” soon brought skyrocketing public demand.

Rockefeller had purchased considerable amounts of production from the Lima oilfield at bargain prices. Most experts in the new petroleum industry believed the thick oil virtually worthless. It could not be refined for a profit. The Whiting refinery, using a newly patented method, efficiently processed Ohio sour oil into high-quality kerosene.

Although gasoline was a minor by-product, two brothers in Massachusetts were building a gasoline-powered horseless carriage at about the time the refinery produced its first 125 railroad tank cars filled with kerosene. The gas-powered automobile helped relaunch the petroleum industry — see Cantankerous Combustion – 1st U.S. Auto Show.

“By the mid-1890s, the Whiting plant had become the largest refinery in the United States, handling 36,000 barrels of oil per day and accounting for nearly 20 percent of the total U.S. refining capacity” noted historian Mark R. Wilson in the Encyclopedia of Chicago. Initially it consisted of just a single facility, adds a company history on the Amoco website.

The Standard Oil refinery in Whiting, Indiana, became the company’s most productive. Owned by BP since 1998, it has remained the largest U.S. refinery. Whiting has been home to the Northwest Indiana Oilmen since 2012.

Crude oil was processed into products that people and business needed: axle grease for industrial machinery, paraffin wax for candles, kerosene for home lighting.

“The company grew. By the early 1900s it was the leading provider of kerosene and gasoline in the Midwest” noted Wilson on the website. “Kerosene sales would eventually falter. But with car ownership booming across the United States, demand for gasoline would only go up and up.”

More Midwest Refineries

By 1910, the refinery is connected by pipeline to oilfields in Kansas and Oklahoma, as well as Ohio and Indiana. The Whiting facility employs 2,400 workers. In 1911, when Rockefeller was forced to break up his oil holdings, Standard of Indiana, with its main offices in downtown Chicago, emerged as an independent company.

Rockefeller’s Whiting scientists had patented a process they invented called thermal cracking, notes the Amoco website. It doubled the amount of gasoline that could be made from a barrel of oil and also boosted the gasoline’s octane rating.

Standard Oil’s process, which became standard practice in the refining industry, helped avert a gasoline shortage during World War I. To find its own oil supplies, Standard Oil of Indiana began its own exploration and production business, Stanolind.

In 1922, Standard Oil absorbed the American Oil Company, founded in Baltimore in 1910, and began branding products as Amoco, which later would become its company name. By 1952, Amoco was ranked as the largest domestic oil company.

During the second half of the twentieth century, the U.S. refining industry became more concentrated in Texas, Louisiana, and California.

“The Chicago region became somewhat less important as an oil-processing center than it had been during the previous 60 years,” historian Mark Wilson concluded. “Still, the area remained home to some large refineries. The largest of these plants was the one at Whiting – the same facility that had brought refining to Chicago in 1890.”

Across the border from Indiana, three major Illinois refineries also process oil in the Chicago area. At the end of 2021, the Citgo refinery in Lemont processed 177,000 barrels of oil a day; the Joliet refinery owned by ExxonMobil processed 248,000 barrels of oil a day; and the Robinson refinery of Marathon Petroleum Company processed 192,000 barrels of oil a day (with a reported capacity for 253,000 barrels).

Refining Museum

A fourth refinery located in southern Illinois — and is almost as historic as Rockefeller’s Whiting plant — was constructed in 1918 by Shell. The giant Wood River Refinery has operated north of St. Louis along the Mississippi River.

The refinery, owned since 2013 by ConocoPhillips, has continued to be company’s largest — processing 380,000 barrels of oil daily into millions of gallons of gasoline/fuel and thousands of barrels of asphalt. The Whiting refinery also has its own museum.

“The Wood River Refinery History Museum is located in front of the Conoco-Phillips Refinery on Highway 111 in Wood River, Illinois,” the museum notes on its website. “There are four buildings in our complex, so to see most of our collection, plan on spending some time.”

Whiting fielded a baseball team in 2012. The Northwest Indiana Oilmen is one of eight teams in the Midwest Collegiate League, a pre-minor league. To learn more about other petroleum history related baseball teams, see Oilfields of Dreams.

By 1982, Standard of Indiana refineries produce 1.2 million barrels of gasoline daily and serve 18,000 domestic gasoline retail outlets. Standard’s two largest refineries are located in Whiting and Texas City, Texas. Standard Oil of Indiana became Amoco Corporation in 1985 and three years later merged with British Petroleum (BP), the world’s largest industrial merger at the time.

_______________________

Recommended Reading: Titan: The Life of John D. Rockefeller, Sr. (2004); Whiting and Robertsdale – Images of America

(2004); Whiting and Robertsdale – Images of America (2013). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

(2013). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.

_______________________

The American Oil & Gas Historical Society (AOGHS) preserves U.S. petroleum history. Become an AOGHS annual supporting member and help maintain this energy education website and expand historical research. For more information, contact bawells@aoghs.org. © 2023 Bruce A. Wells. All rights reserved.

Citation Information – Article Title: “Standard Oil Whiting Refinery.” Authors: B.A. Wells and K.L. Wells. Website Name: American Oil & Gas Historical Society. URL: https://aoghs.org/products/standard-oil-whiting-refinery. Last Updated: April 27, 2023. Original Published Date: June 15, 2013.

(2008); Unleaded: How Changing Our Gasoline Changed Everything (2021). Your Amazon purchase benefits the American Oil & Gas Historical Society. As an Amazon Associate, AOGHS earns a commission from qualifying purchases.